(1) Precautions for storage of special gas cylinders (cylinders)

1, special gas cylinders (cylinders) should be stored in a special warehouse, special gas cylinders (cylinders) warehouse should comply with the relevant provisions of the Architectural design fire protection code.

2. There shall be no ditches, secret tunnels, open fire and other heat sources in the warehouse. The warehouse should be ventilated, dry, avoid direct sunlight, storage temperature shall not exceed 51.7 ℃; Special gas cylinders (cylinders) should not be placed in artificial low temperature environment. The words "Special gas cylinders (cylinders) Storage" shall be clearly marked in the bottle store, showing the appropriate hazard warning number (e.g. flammable, toxic, radioactive, etc.)

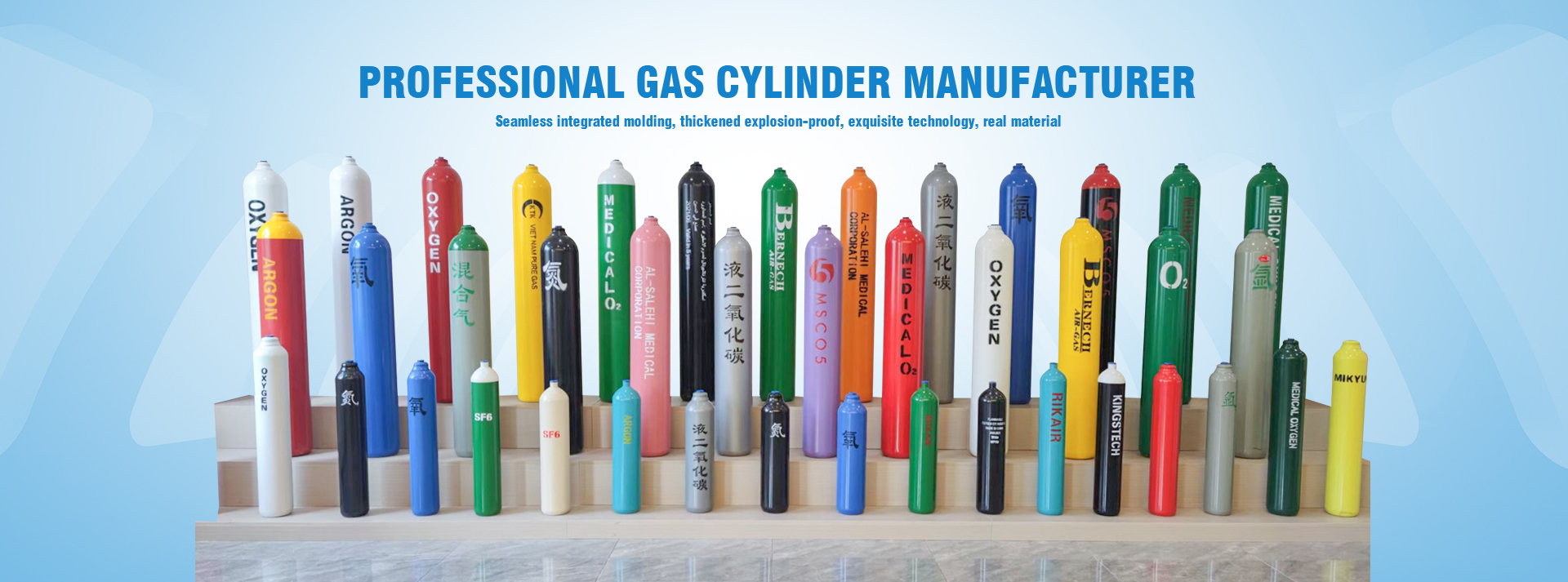

3. Special gas cylinders (cylinders) containing polymerization reaction or decomposition reaction gas must be specified for the storage period, and the radioactive line source should be avoided according to different properties, and the valve turns differently. General rule: Flammable gas Special gas cylinders (cylinders) are red, turn left. Toxic gas (special gas cylinder (gas cylinder) is yellow), non-combustible gas turn right

4, empty or solid bottles should be placed separately, and there are obvious signs, toxic gas special gas cylinders (cylinders) and the contact of the gas in the bottle can cause combustion, explosion, toxic special gas cylinders (cylinders), should be stored in separate rooms, and set up gas appliances or fire fighting equipment nearby.

5. Special gas cylinders (cylinders) should be placed with bottle caps. When standing, it should be fixed properly. Do not put in the passageway to avoid bumping.

6. Special gas cylinders (cylinders) should be stored in places where there is no danger of fire. And away from heat and fire

7. Special gas cylinders (cylinders) stored in the open air should be protected to prevent rust and severe weather erosion. Special gas cylinders (gas cylinders) should be placed on the galvanized iron grid to reduce the bottom corrosion of special gas cylinders (gas cylinders).

8. Special gas cylinders (cylinders) in stock should be stored separately by category. (separating toxic, flammable, etc.)

9. Special gas cylinders (cylinders) containing oxygen and oxidant must be stored separately from combustible gas by a firewall.

10, flammable or toxic gas storage should be kept at a minimum.

11. Special gas cylinders containing combustible gases (cylinders) should be kept away from other flammable materials

12, the storage of special gas cylinders (cylinders) to be checked regularly. Such as appearance, whether there is a leak. And take notes

13, before entering the storage area containing combustible or toxic gases to determine the content of flammable and toxic gases in the atmosphere. An automatic alarm device shall be installed in the special gas cylinder (cylinder) storage for toxic, combustible or asphyxiating gases.

(2) Precautions for the use of special gas cylinders (cylinders)

1. It is not allowed to change the seal and color mark of special gas cylinders (cylinders) without authorization. Do not scrawl or label on cylinders.

2, special gas cylinders (cylinders) should be checked for safety before use, to confirm the medium in the bottle. See MSDS clearly before use and operate in strict accordance with safety regulations (corrosive gas cylinders, inspected every 2 years, inert gas cylinders, inspected every 5 years, general gas every 3 years. Cylinder life is 30 years)

3, special gas cylinders (cylinders) shall not be placed near the heat source, 10 meters away from the open fire, special gas cylinders (cylinders) containing polymerization reaction or decomposition reaction gas, should avoid radioactive sources.

4, special gas cylinders (cylinders) should take anti-dumping measures when standing. Avoid dragging, rolling and sliding specialty gas cylinders (cylinders).

5, it is strictly prohibited to arc welding on special gas cylinders (cylinders).

6, prevent exposure, do not knock, collision. Avoid handling special gas cylinders (cylinders) by greasy hands, gloves or rags.

7. It is strictly prohibited to heat special gas cylinders (cylinders) with a heat source exceeding 40℃, and never directly use open fire or electric heating to increase the pressure of special gas cylinders (cylinders).

8. If necessary, wear protective gloves, safety eyes, chemical goggles or face masks, and use positive pressure breathing apparatus or self-contained breathing apparatus near the working place.

9, general gas can be used soap water leak detection, toxic gas or corrosive gas to use a special method of leak detection.

10. There should be enough spare water in the working area. Water can be used as the first step to rescue fire extinguishing, or dilute the corrosion that leaks out accidentally. The working area should also be equipped with foam fire extinguishing agent, dry powder fire extinguisher, special detoxification and neutralizing substances in reaction according to different types of gas

11. When supplying air to the system, the suitable pressure reducer and pipes, valves and accessories should be selected

12, in the use of possible backflow, the use of equipment must be configured to prevent backflow device, such as check valve, check valve, buffer, etc..

Never allow the volume of liquefied gas to exist in a certain part of the system

14. Confirm that the electrical system is suitable for working gas. When using combustible gas special gas cylinders (gas cylinders), the cylinders, pipes, and equipment must be uniformly grounded.

15. Do not attempt to transfer gas from one special gas cylinder (cylinder) to another.

16. Special gas cylinders (cylinders) shall not be used as rollers, supports or for other purposes.

17. Never allow oil, grease or other inflammables to come into contact with valves containing oxidizing special gas cylinders (cylinders).

18, do not attempt to repair or change special gas cylinder (cylinder) valve or safety device, valve damage should immediately report to the supplier.

19, in the middle of the temporary use of gas, that is, the cylinder is still connected to the system, but also to close the special gas cylinder (cylinder) valve, and do a good mark

20, toxic gas workshop should have a good exhaust device, before the operator into the workshop, indoor ventilation should be first, it is possible to carry an alarm into the.

21, operators in contact with toxic gas, must wear appropriate safe labor supplies, and must have two people at the same time, one of the operation, another person as an assistant.

22, special gas cylinders (cylinders) in the gas shall not be used up, must have residual pressure, permanent residual pressure of gas is not less than 0.05mpa, liquefied gas special gas cylinders (cylinders) should have no less than 0.5-1.0% regulation charge.

Post time: Jul-07-2022