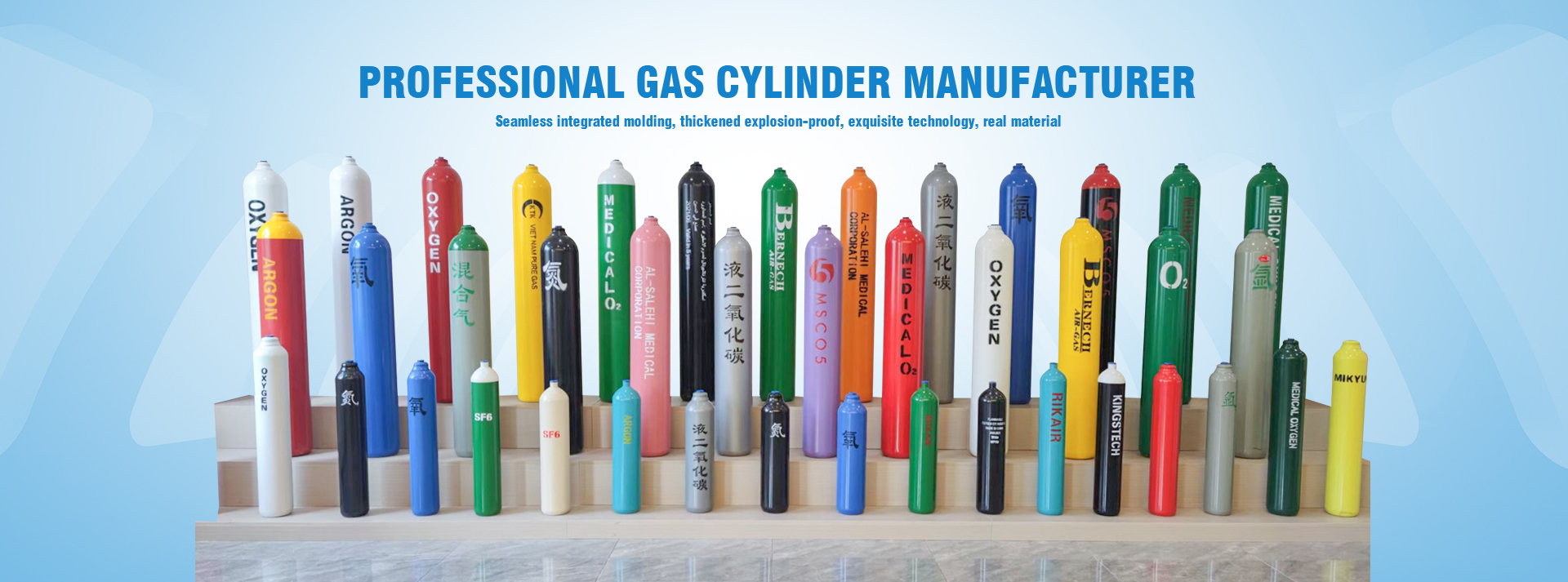

Seamless gas cylinders are classified according to manufacturing raw materials:

1. Steel seamless gas cylinder

It is a steel cylinder made of steel billet as raw material, stamped and stretched, or seamless steel pipe as material, and made of hot spinning to close the mouth and bottom. The material of the bottle body is killed steel smelted by alkaline open hearth, electric furnace or oxygen-blown alkaline converter, such as high-quality carbon steel, manganese steel, chromium-molybdenum steel or other alloy steel. Used to contain long-term gas (compressed gas) and high-pressure liquefied gas.

2. Steel welded gas cylinders

It is a steel cylinder made of steel plate as raw material and stamped and coiled. The material of the bottle body and pressure-bearing components is killed steel smelted in an open-hearth furnace, an electric furnace or an oxidation converter. The material requires good stamping and welding properties. This type of cylinder is used to contain low-pressure liquefied gas.

3. Winding fiberglass cylinders

It is a gas cylinder made of glass fiber and binder winding or carbon fiber. Generally, there is an aluminum inner cylinder, which is used to ensure the air tightness of the cylinder. The pressure-bearing strength relies on the outer cylinder wrapped with glass fiber. This type of cylinder is mostly used to contain compressed air for breathing due to its good thermal insulation performance and light weight. , for workers working in firefighting, poisonous areas or hypoxic areas to carry around and use with masks. Generally, the volume is small (1~10L), and the inflation pressure is mostly 15~30MPa.

Post time: Jan-05-2024